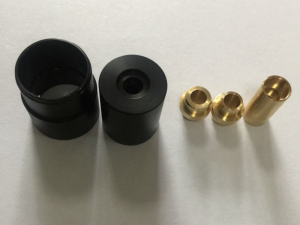

Babban madaidaicin Swiss CNC machining matte ruwa shaft

Ƙayyadaddun samfur

| Sunan samfur | Bakin shaft |

| Kayan abu | 420J2 bakin karfe |

| Tsarin sarrafawa | Swiss CNC machining |

| Maganin Sama | Burrs cirewa |

| Hakuri | +/-0.002~+/-0.005mm |

| Tashin Lafiya | Min Ra0.1~3.2 |

| An Karɓar Zane | STP, Mataki, LGS, XT, AutoCAD (DXF, DWG), PDF, ko Samfura |

| Amfani | Masana'antu |

| Lokacin Jagora | 1-2 makonni don samfurori, 3-4 makonni don samar da taro |

| Tabbacin inganci | ISO9001: 2015, SGS, RoHs |

| Sharuɗɗan Biyan kuɗi | Tabbatar da Kasuwanci, TT/PayPal/West Union |

Fasahar Machining ta Star ta yi amfani da shafts da hannayen riga don masana'antu da yawa na shekaru masu yawa.Ana ba da nau'i-nau'i na Na'urorin haɗi na Shaft da mu.Ana samun madaidaicin madaidaicin ingartaccen shaft/hub clamps a cikin. salo da yawa daban-daban da girma dabam don ɗaure ginshiƙai, jakunkuna da bugun kira zuwa ga shaft.

Marufi & Bayarwa

Marufi:hannun rigar filastik akan ƙarshen kaifi, da wasu pcs a cikin buhunan kumfa, wasu jakunkuna kaɗan a cikin akwatin kwali wanda bai wuce 22 KGS ba.

Bayarwa:Isar da samfuran kusan7 ~ 15 days da gubar lokaci domin taro samar ne game da 25-40 days.

FAQ

●Shin kamfanin ku yana da kowane irin takaddun shaida mai inganci?

Ee, mu AS9100 Rev C / ISO 9001: 2008 ingancin bokan

●Yaya tsawon lokaci kuke buƙatar ba ni magana?

Yawancin lokaci, ana aika zance don samfur a cikin kwanaki 2 bayan mun sami binciken tare da duk mahimman bayanai.

●Shin lokutan jagora a cikin kwanakin aiki ne ko kwanakin kalanda?

Ana ambaton lokutan jagora a cikin kwanakin kalanda.

●Wadanne fayilolin ƙira za ku iya karɓa daga kamfaninmu?

Yawancin shirye-shiryen tushen CAD, misali DWG, DXF, IGES da mafi yawan tsarin da ake amfani da su.

●Kuna bayarwatarohidima?

Ee, muna yin hakan.Za a iya ƙirƙira majalissar injuna ta musamman ta amfani da madaidaicin shafting ɗin mu tare da ginshiƙai, jakunkuna, kayan haɗin gwiwa da bearings daga kaya ko gyara don aikace-aikacen ku.

●Wadanne nau'ikan kayan za a iya yin injin don hannayen riga da sanduna?

Aluminum, bakin karfe, Alloys Copper (Bronze, Brass), Titanium, Nickel Alloys da kowane irin kayan filastik ana iya yin injin.

●Wane tsari na masana'anta ne za a yi amfani da shafts ko hannayen riga?

Mafi yawa ta amfani da CNC juya na iya yin shaft ko hannun riga, wani lokacin CNC milling kuma ana buƙatar amfani da shi don yin ramuka ko sarrafa surar da ba ta dace ba.Idan adadin ya fi girma za mu yi amfani da tsarin juya CNC na swiss don yin su.

samfurori masu dangantaka

-

Tel

-

Imel

-

Whatsapp

-

WeChat

WeChat

-

Sama